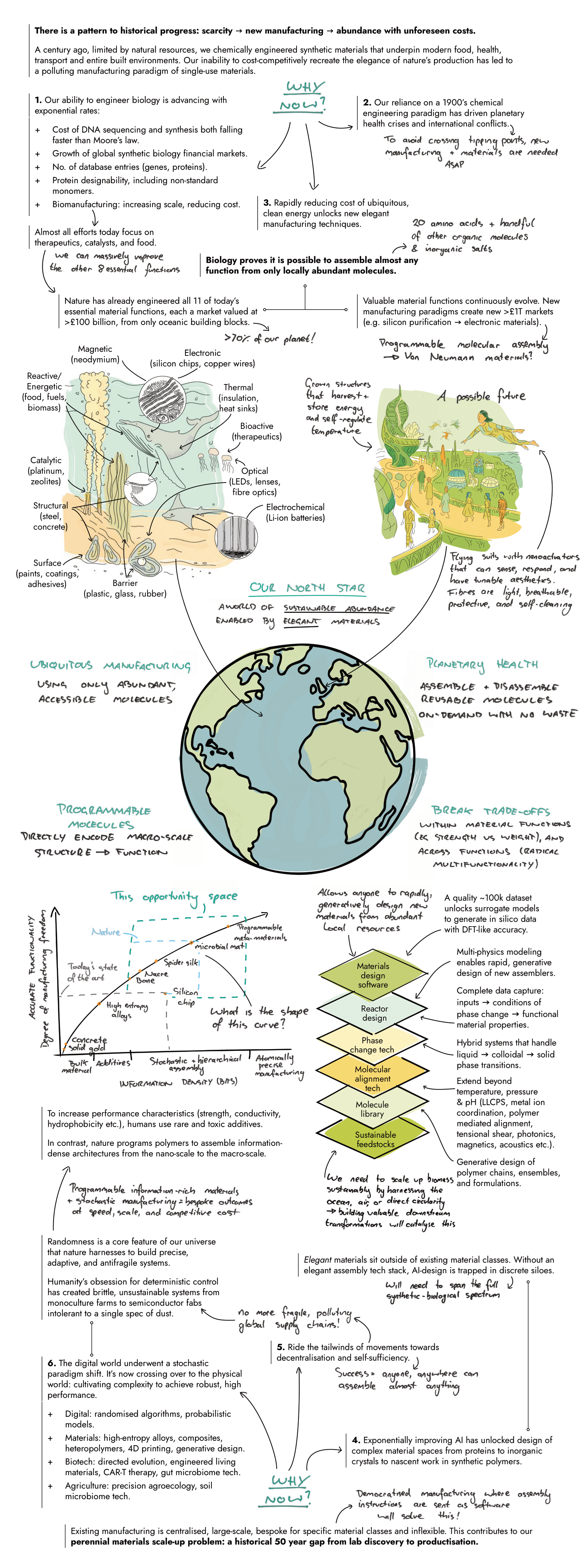

What if we could create a world of sustainable abundance by revolutionising our manufacturing paradigm?

Defined by our Programme Directors (PDs), opportunity spaces are areas we believe are likely to yield breakthroughs.

In Manufacturing Abundance, we're exploring how the ability to assemble molecules into bespoke materials could solve today’s great challenges and finally unlock sustainable abundance.

Beliefs

The core beliefs that underpin this opportunity space:

We will assemble limited sets of available molecules into a limitless range of functionality, without cost to planetary health.

Programmable polymers will construct materials, from the nanoscale to the macroscale, with structures that deliver tailored performance with unprecedented accuracy.

Ubiquitous clean energy will unlock a new manufacturing paradigm and, in turn, be catalysed by it: cost-competitive, precise performance arising from structure (vs. composition) and stochastic (vs. deterministic) assembly.

To unlock ubiquitous manufacturing, we’ll need a new biotic-abiotic tech stack that lets us programmably assemble matter like software → creating resilient societies, unleashing innovation at scale, and shrinking lab-to-market cycles from decades to days.

Programme: Universal Fabricators

To build a programme within an opportunity space, our Programme Directors direct the review, selection, and funding of a portfolio of projects.

Backed by £50m, our Universal Fabricators programme seeks to harness proteins to produce a functionally universal range of materials at scale.

We’re now seeking applications from teams to develop scalable processes that use proteins to template the assembly of inorganic and composite materials with structures that currently cannot be mass manufactured. This programme is designed to expand the Overton window in this domain – to move from biology into first-principles manufacturing approaches.

Sign up for updates

Stay up-to-date on our opportunity spaces and programmes, be the first to know about our funding calls and get the latest news from ARIA.